Poly vs Epoxy Boards: The Difference

Poly vs Epoxy Boards: What’s The Difference?

When you buy or rent a surfboard, you probably don’t give much thought to the process that goes into making it. Who was the shaper? Where was it made? What type of foam blank was used? What type of resin was used to coat the board? While these are all valid questions the one we get asked the most often is what is the difference between poly vs epoxy boards?

Epoxy(right) vs Poly(left)

Poly Technology

Polyurethane blanks (PU) date back to the 50’s, when Hobie Alter first popularized the design as an alternative to balsa wood. When compared to traditional wood boards, PU foam is lighter, easier to shape, and enhances performance. According to the American Chemistry Council, “polyurethanes are formed by reacting a polyol (an alcohol with more than two reactive hydroxyl groups per molecule) with a diisocyanate or a polymeric isocyanate in the presence of suitable catalysts and additives.” PU/PE are built using a polyurethane foam blank and then glassing it with a polyester resin. A particular draw of using PU foam is that it is closed cell—meaning it won’t easily soak up resin or water (should you ding your board), which helps keep the board light.

Poly Surboard

Epoxy Technology

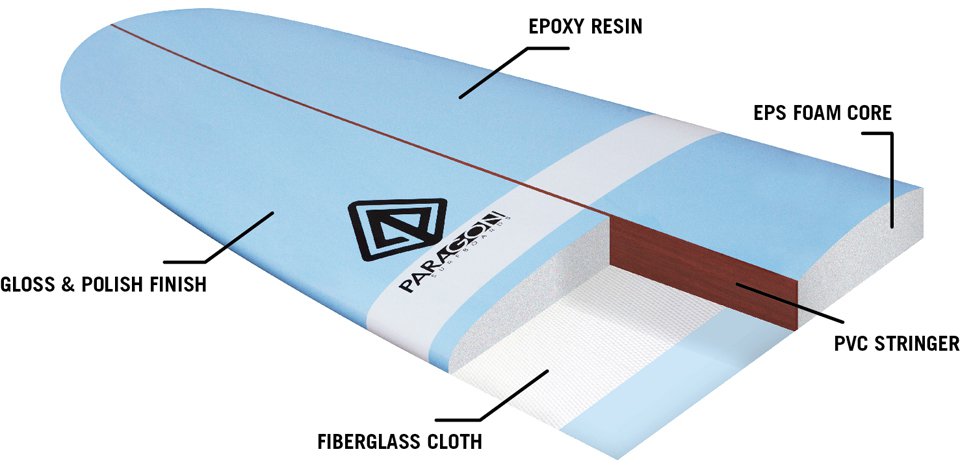

Epoxy surfboards came into the picture a bit later and it wasn’t until the 90’s that they really caught on. Typically, epoxy boards are made from EPS foam and are coated in epoxy resin. EPS foam is produced by feeding tiny polystyrene spears into a machine and then adding steam (with small amounts of pentane gas) to expand the beads and then mold them together. EPS is an open cell foam, meaning it’s extremely water absorbent. In order to keep the board water tight, shapers add extra layers of fiberglass and epoxy resin. Traditionally, most hand shapers don’t make boards from EPS foam but it is a great resource for pop-out boards.

Epoxy Surfboard

Pros and Cons: Poly vs Epoxy

Like most things in life, there are pros and cons to each design. Surfers tend to like different boards for different conditions and some surfers surf better on different types of boards because of body structure. In general, PU/PE boards are cheaper than EPS/Epoxy boards. Poly boards tend to be heavier, which means they sit lower in the water, making them the ideal design for riding barrels. They are also a lot more flexible, something that has yet to fully be matched with EPS foam. Most poly boards will be more fragile then epoxy because epoxy material is harder than poly. If you want to try out certain equipment before buying it and dont know where the best wave is to do that at, go to Bolsa Chica State Beach #1 Rated Beach to Learn To Surf to get an understanding how we at Corky Carroll’s Surf School Private Lessons do it!

Epoxy boards, on the other hand, are much lighter, making them the perfect board for airs or quick turns. Epoxy boards also tend to be a better option for beginners as they are lighter, float better, and are more difficult to ding. EPS foam is also more environmentally friendly than polyurethane because it can be recycled and re-purposed.

There is no wrong or right choice when selecting a surfboard—do your research and decide what is the best fit for you. Before investing in a board of your own, consider renting or demoing to find your best fit.

Corky Carroll’s Surf School

If you are a beginner surfer or just need some more progressive tips but are scared to use a hard surfboard go check out why Foam Surfboards are our number one board to use! Do not buy just any foam surfboard, go check out Why You Shouldnt Buy A Costco Surfboard!

Here, at Corky Carroll’s, we offer a Surf School in Huntington Beach, California or Our Costa Rican Surf Resort in Nosara, Costa Rica. We have a wide fleet of boards to choose from and are happy to answer any questions you might have. Poly or epoxy, the choice is yours. We’re just glad you’re out in the water and riding waves.

Hi,

Although this article is old, I figured I’d point out something I noticed since it is one of the top results and I want the material to be accurate for people trying to decide on surfboard construction. There is a slight lapse in reasoning regarding the discussion about flexibility, fragility, and ding susceptibility. It is pointed out that poly is less hard than poly, therefore poly is more fragile. This is misleading because a harder material, especially epoxy, will generally be more brittle i.e. sustain less deformation before failure and also have a lower impact strength. A lower impact strength means when a load is quickly applied, it is expected that cured polyester resin will deform more/absorb more energy before failure whereas cured epoxy will easily fail/crack with little energy absorbed. This is a standardized material test we do in materials science. In a surfboard, this could be seen as divots in a poly board vs. cracking in epoxy when a quick impact is sustained like hitting a rock or another board. The higher strength of epoxy only applies at low strain rates, or slow rate of loading (think slowly pulling on a bar of material rather than hitting it with a hammer). When we think of the term “fragile” as being a measure of complete failure under a certain condition, this should be given to epoxy. From this reasoning, it’s better to say (if at all) that poly boards are more difficult to ding. For background, I’m a fourth year materials science student at UCLA and I work in a polymer lab in industry at the moment. The lead engineer, who has several years experience in polymer science and a PhD candidate discussed this with me and we both agree on this. Since people don’t really collect data on surfboard repairs, it’s hard to state anything for certain, but we can use basic material properties as a guideline.

For example, if you expect a beginner board to sustain quite a few dings, and because epoxy boards will likely experience catastrophic crack propagation combined with expensive board and repairs, and high water absorbency in the case of cracking, poly boards suddenly seem more attractive to a beginner surfer. Of course, there are many more variables like amount of resin applied, reinforcement, bonding to foam, etc., but I’d expect a beginner surfboard to generally be more conservative in construction for cost savings and I’d argue to suggest poly boards for beginners in most cases, at least until someone modifies epoxy resin to be cheaper and have higher impact strength. In theory, this will save new accident-prone surfers the hassle of continuously repairing their expensive board/buying another epoxy board with the same issues.

With the higher tensile strength of epoxy boards, I see the benefits for an advanced surfer, since the board will probably last longer by experiencing less pressure zones from explosive turns and all that. The lightness too a perk for some people.

Let me know if there’s something I’m missing in this in terms of surfboard construction!

– Dillon